VISION LIMITED

Our company was founded in 1970 and is run as a family business. We focus on providing secondary processing services to our industry peers and have successfully established a significant position in the southern market in a short period of time with strong customer support and love. Despite the challenges of several economic downturns, these experiences have given our decision-makers a deep understanding of the importance of automation to business survival. Therefore, we have introduced automatic lathes on a large scale to cope with the growing business needs. In addition, we have also invested heavily in purchasing multiple CNC lathes and automated processing equipment to improve manufacturing efficiency and precision, realize our commitment to sustainable operations, and contribute to various industries.

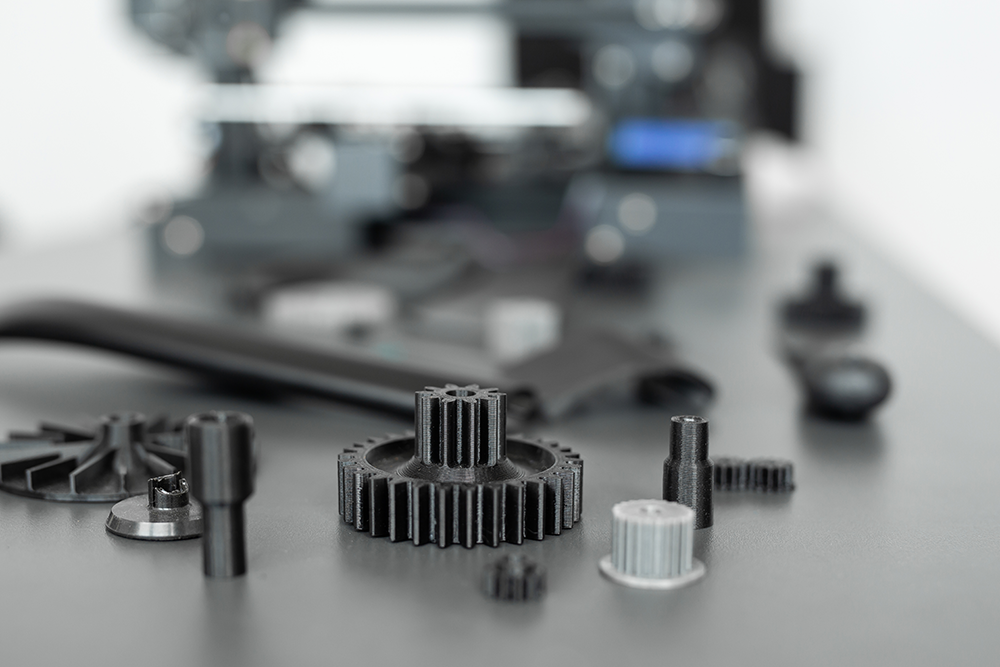

Fastener processing

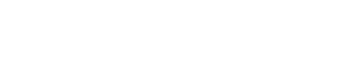

CNC machining/CNC machining

rubber parts

We are committed to providing world-class quality fastener processing, CNC machining, rubber parts and plastic parts manufacturing services.

With world-leading technical strength and precision manufacturing processes, every product we produce meets international standards and passes strict quality testing to ensure zero defects and excellent performance. Our CNC processing equipment has micron-level precision and can meet the most complex requirements. design needs, providing high-precision customized solutions for all walks of life,

In addition, we use the latest material technology and automation equipment in the production of rubber and plastic parts to ensure the durability and stability of our products. With years of accumulated professional experience and continuous innovative technology, we not only rank among the best in the world in terms of quality. It has won the trust and recognition of global customers with its excellent technology.

Our competitive advantage

Quality assurance

Professional team

Competitive price

Professional technology, quality assurance

Guaranteed Quality with Professional Expertise

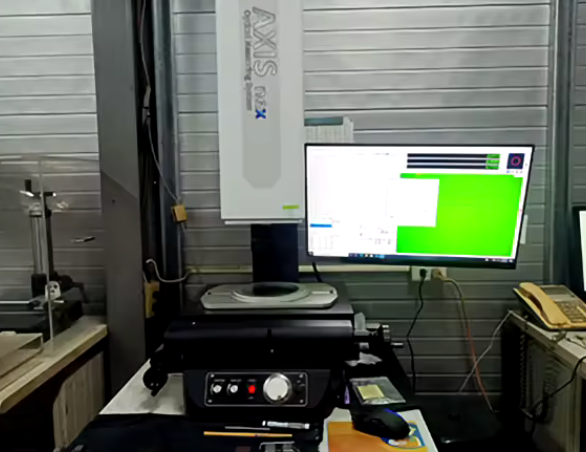

our environment

Adhering to the business philosophy of "excellence, quality first", we are committed to creating an advanced production environment. The factory is equipped with the latest automation equipment and CNC processing machines, and strictly follows international standards for production to ensure the efficiency and accuracy of every process. Our production line has a reasonable layout. From raw material inspection, processing and manufacturing to final product testing, we adopt full digital management to ensure stable and consistent product quality. In order to improve production efficiency and environmental benefits, we have adopted an intelligent management system and built a International standard dust-free workshop provides the most ideal manufacturing environment.

In addition, we have a professional technical team and rigorous quality control processes to continuously promote technological innovation to ensure that we can meet the needs of various industries and provide excellent manufacturing solutions to customers around the world.